The supports are automatically generated with optimal dimensions for your printed parts based on material and part geometry.

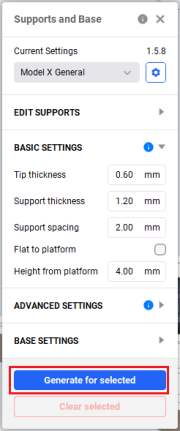

To auto-generate the supports for your model:

1. Press the ![]() icon on the left Toolbar.

icon on the left Toolbar.

→ The dialog box opens.

2. Press Generate for Selected.

→ Supports are added to the selected mode.

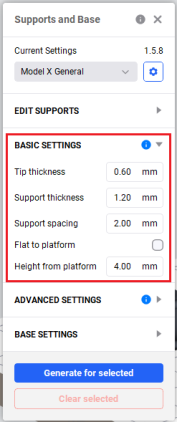

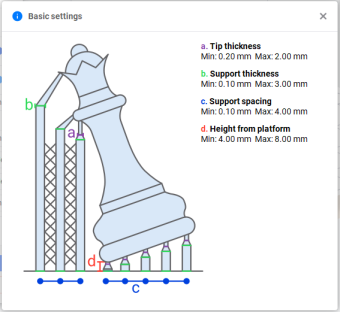

Basic Settings

|

Tip thickness: Defines the thickness of the cone tip at the upper and lower end of the support beam. Support thickness: Defines the thickness of the entire support beam. Support spacing: Defines the distance between the support beams. Flat to platform: When enabled, this option ensures that the model is built without supports and baseplate. Height from platform: Defines the height of the support structures. |

|

icon next to the Base Settings in the Supports and Base widget to see the range of allowable values for each parameter.

icon next to the Base Settings in the Supports and Base widget to see the range of allowable values for each parameter.

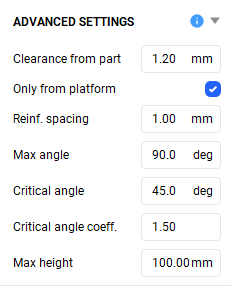

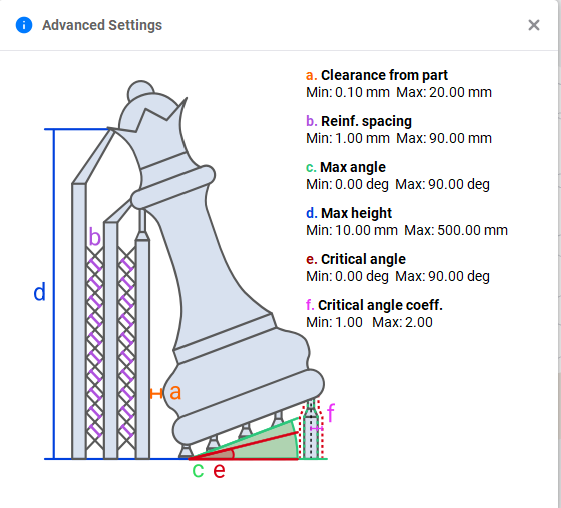

Advanced Settings

|

Clearance from part: Determines the required distance between each beam and the adjacent surface of the model. Only from platform: When enabled, this parameter indicates that support structures must attach to the platform only. The model-to-model support structures are not built. Reinf. Spacing: Determines the allowable distance between the reinforcing cross bars. Max. Angle: Determines the maximum angle between the model and the build platform from which supports will be built. Critical Angle: Identifies the area where supports are most essential for stability and structure, requiring the greatest attention. Critical Angle Coefficient: Automatically adjusts support structures by calculating the Tip Thickness For Critical Area and Support Thickness For Critical Area. Max. Height: Specifies the maximum height of supports for the model structure above the build platform. |

|

icon next to the Advanced Settings in the Supports and Base widget to view the allowed value range for each parameter.

icon next to the Advanced Settings in the Supports and Base widget to view the allowed value range for each parameter.

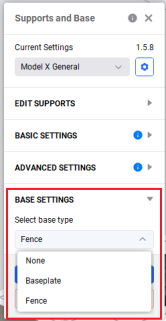

Base Settings

Decide whether you want to include the base for the models. For that, check the parameters in the BASE SETTINGS section of the Supports and Base widget.

|

None: No base is created for the model(s) on the platform. This option is automatically set in the Base Type drop-down when the Flat to platform option is enabled in the Basic Settings menu. Baseplate: A model and its supports are built on the baseplate. Fence: The fences are built between neighboring support beams to ensure more stability for support structures. |

|